Unstable temperatures can quietly cause big problems in the workplace. Overheated machines, uncomfortable workers, and damaged products are just a few examples of what happens when conditions aren’t properly managed. These issues hurt productivity, increase costs, and can even put people at risk.

Advanced temperature control systems are built to prevent those problems. They use sensors, automated controllers, and real-time feedback to keep environments steady and safe. This article explains how these systems work, their main components, and how they reduce risks in different industries.

Why Temperature Control Matters in the Workplace

Keeping the right temperature isn’t just about comfort. It directly affects safety, performance, and the reliability of equipment.

Common Risks Caused by Poor Temperature Regulation

When temperatures swing too high or too low, serious problems can occur. Machines might overheat or freeze, leading to breakdowns or costly repairs. In industries where sensitive electronics or heavy-duty equipment operate under extreme heat, traditional cooling units may not provide enough precision or durability. In such cases, a mil-spec ECU can offer the rugged, reliable cooling needed to maintain stability and prevent failure even in demanding environments.

Workers can also experience fatigue or heat stress, which reduces focus and increases the chance of accidents. In places like food storage facilities or manufacturing plants, unstable temperatures can spoil products or lower their quality.

Without reliable temperature control, companies often lose money through wasted materials, damaged machinery, and medical costs. Stable conditions are therefore a vital part of maintaining both safety and efficiency.

How Temperature Affects Productivity and Safety

Temperature also plays a big role in how people work. Productivity drops by as much as 4% for every degree above 77°F (25°C). Even small temperature changes can affect focus and performance.

Stable workplace conditions also help companies meet safety standards and prevent temperature-related health problems. When both equipment and workers operate within safe limits, the work environment becomes more reliable and productive.

Core Components of Modern Temperature Control Systems

To understand how these systems protect workplaces, it helps to know how their parts work together.

Temperature Sensors and Sensor Data

Everything begins with the temperature sensor. This device measures the environment and sends real-time readings to the control unit. Accurate sensor data ensures the system reacts correctly whenever conditions shift.

Control Units and Feedback Control Systems

The control unit is the system’s brain. It reads data from the sensors and decides whether to adjust the heating or cooling elements. Using a feedback control system, it constantly compares the current temperature to the set point and makes precise corrections to stay within range.

PID Controllers and On/Off Control

Basic systems use on/off control. They switch the heater or cooler completely on or off when the temperature crosses a certain point. More advanced systems use PID (proportional-integral-derivative) controllers. These adjust the output in smaller steps to avoid overshooting and keep temperatures stable. As a result, the system uses less energy and extends the life of connected equipment.

Advanced Temperature Controllers and Their Working Mechanism

Modern control systems rely on automation to achieve precise, consistent results.

Maintaining the Desired Temperature Through Automation

Here’s how a typical system works:

- Sensing: The sensor checks the temperature.

- Comparing: The controller compares it to the desired set point.

- Adjusting: The system activates the heating or cooling element to correct the difference.

This process happens constantly, often several times per second. Because of this, the temperature stays steady, and the risk of overheating or overcooling is reduced.

Integration With HVAC Systems and Air Conditioners

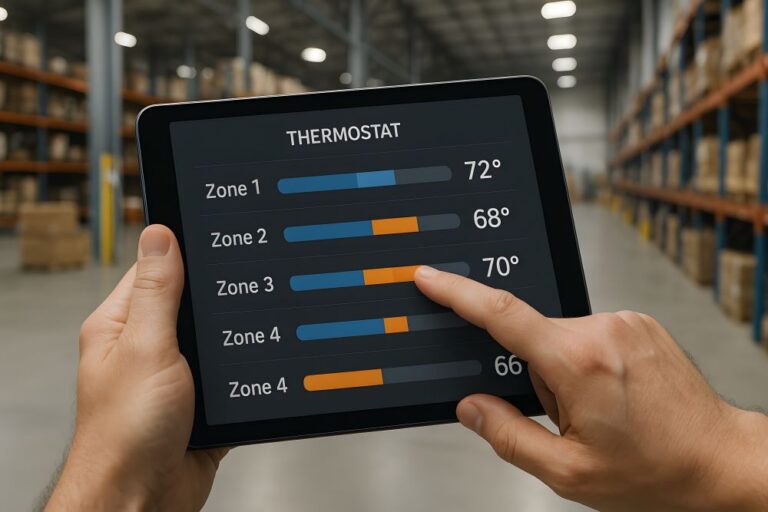

In office buildings and industrial spaces, temperature controllers connect directly to HVAC systems and air conditioners. They coordinate airflow, humidity, and cooling elements such as heat pumps or recirculating chillers. This ensures consistent comfort while maintaining energy efficiency.

Safety Limit Controllers and Risk Prevention

Safety limit controllers add another layer of protection. If temperatures go beyond safe limits, they trigger alarms or shut down equipment. This helps prevent fires, overheating, and other hazards. Industries like food processing, pharmaceuticals, and laboratories depend on these systems to protect workers and materials.

Real-World Applications Across Industries

Temperature control systems or environmental control units are used everywhere precision and safety matter.

Manufacturing and Industrial Applications

Factories depend on accurate temperature regulation to keep machines running correctly. Equipment like molding machines, furnaces, and reactors must stay within specific ranges to avoid failure or product defects. In commercial heating operations, advanced systems also help maintain steady performance under heavy workloads.

Food and Pharmaceutical Sectors

In food production and pharmaceutical manufacturing, even small temperature changes can cause spoilage or make a product unsafe. Advanced control units maintain steady conditions for processing, packaging, and storage. This protects product quality and ensures compliance with health and safety regulations.

Office and Commercial Buildings

In offices and retail spaces, smart temperature controllers automatically balance airflow and cooling throughout the day. Automated HVAC systems can lower energy costs by learning usage patterns and adjusting on their own. The result is better comfort, reduced energy waste, and lower utility bills.

Benefits of Implementing Advanced Control Systems

Companies that upgrade their temperature systems often see both immediate and long-term improvements.

- Less Downtime: Prevents overheating or freezing that can stop operations.

- Improved Safety: Advanced monitoring reduces accident risks and helps maintain safe working conditions.

- Energy Efficiency: Smart control logic minimizes power use during daily operations.

- Longer Equipment Life: Heating and cooling elements experience less wear and tear.

- Consistent Product Quality: Keeps environmental conditions within the required limits.

These results lead to smoother operations, stronger safety records, and measurable cost savings over time.

Choosing the Right Temperature Control Solution

The right temperature control system depends on each workplace’s specific needs.

Before purchasing, consider factors such as the type of process, required temperature range, and safety conditions. Make sure the sensors, controllers, and heating or cooling elements are compatible with each other. In larger or more complex setups like recirculating chillers, professional installation and calibration are highly recommended. Proper setup ensures accuracy, prevents downtime, and keeps the system running efficiently.

Conclusion

Temperature control plays a major role in workplace safety, efficiency, and product quality. Advanced control systems combine accurate sensors, intelligent feedback, and automated adjustments to maintain ideal conditions.

Upgrading outdated systems helps companies reduce risks, protect workers, and save energy. Over time, these systems pay for themselves through fewer breakdowns, lower costs, and a safer, more reliable work environment.